Product Description:

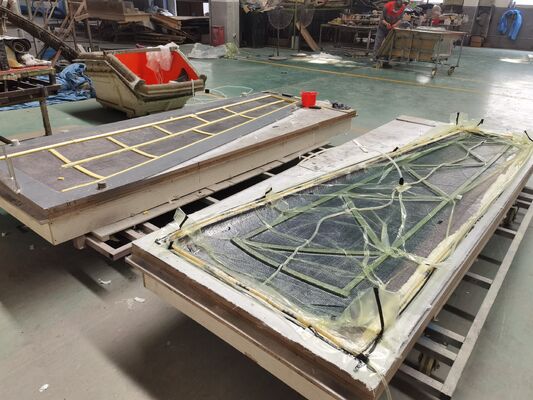

The FRP Mould is a highly durable and versatile tool designed to meet the rigorous demands of various industries, including automotive, renewable energy, and composite manufacturing. Known for its exceptional impact resistance, this mould offers superior strength and resilience, ensuring long-lasting performance even under challenging conditions. Whether used in the production of Automotive FRP molds, Composite molds, or Wind turbine FRP molds, this product stands out as a reliable choice for manufacturers seeking quality and efficiency.

One of the key attributes of the FRP Mould is its robust impact resistance. This feature makes it especially suitable for applications where the mould must withstand repeated mechanical stresses and potential impacts during the manufacturing process. The strong impact resistance ensures that the mould maintains its structural integrity over time, reducing the likelihood of cracks, deformations, or failures that can compromise the quality of the final product.

The FRP Mould is designed with precision using advanced CNC machine control technologies. This high level of control allows for intricate and accurate mould designs, delivering consistent and repeatable results. CNC machining guarantees that every mould produced meets stringent dimensional tolerances and surface specifications, which is crucial when manufacturing complex parts such as automotive components or wind turbine blades. The precision offered by CNC control not only enhances the mould’s performance but also improves the overall efficiency of the production process.

Surface finish is another standout feature of the FRP Mould. The mould is crafted to have a smooth surface finish, which is essential for producing high-quality composite parts with excellent aesthetic appeal and structural integrity. A smooth surface finish reduces the need for extensive post-processing on the molded parts, saving time and reducing production costs. Additionally, a polished surface helps in easy demolding and prevents defects such as surface blemishes or uneven textures.

Chemical resistance is a critical factor in the selection of mould materials, especially when dealing with various resins and curing agents used in composite manufacturing. The FRP Mould exhibits strong chemical resistance, enabling it to withstand exposure to harsh chemicals without degrading or losing its mechanical properties. This resistance ensures that the mould can be used repeatedly in demanding chemical environments, thereby extending its service life and maintaining consistent product quality.

Manufacturers can benefit from flexible service options with the FRP Mould, available through both ODM (Original Design Manufacturer) and OEM (Original Equipment Manufacturer) services. This flexibility allows clients to either customize the mould design to their specific requirements or choose from standard designs that meet general industry needs. The availability of ODM and OEM services supports a wide range of applications, from bespoke automotive FRP molds tailored to unique vehicle designs to standardized composite molds for wind turbine blade production.

In summary, the FRP Mould is an exceptional product engineered to provide strong impact resistance, smooth surface finish, and robust chemical resistance, all crafted under precise CNC machine control. Its adaptability to both ODM and OEM service models makes it a valuable asset for manufacturers in the automotive, composite, and renewable energy sectors. Whether producing Automotive FRP molds, Composite molds, or Wind turbine FRP molds, this mould delivers reliability, precision, and durability, helping businesses achieve superior manufacturing outcomes with enhanced efficiency and quality.

Features:

- Durable composite mold construction for long-lasting performance

- Precision control using CNC Machine technology

- Customizable color options to meet specific design requirements

- Available as ODM or OEM service to suit your production needs

- Lightweight FRP tooling for easy handling and installation

- Size customizable to fit various applications and specifications

- High-quality FRP mold ensuring superior finish and durability

Technical Parameters:

| Material |

Fiberglass Reinforced Plastic |

| Mold Type |

Customizable |

| Size |

Customizable |

| Control |

CNC Machine |

| Surface |

Gel Coat Paint |

| Shape |

Customizable |

| Chemical Resistance |

Strong |

| Corrosion Resistance |

Strong |

| Surface Finish |

Smooth |

| Colour |

White Or Other Optional |

Applications:

The LANMON FRP Mould, originating from China, is a highly versatile and customizable molding solution designed to meet the diverse needs of various industries. With its CNC machine control, this mold ensures precision and accuracy in every production cycle, making it ideal for manufacturing components that demand a smooth surface mold finish. The ability to customize the mold type according to specific requirements allows manufacturers to optimize production processes and achieve superior results.

One of the prominent application occasions for the LANMON FRP Mould is in the marine industry. Marine FRP molds are essential for producing high-quality fiberglass reinforced plastic parts used in boats, yachts, and other watercraft. The strong chemical resistance of the LANMON mold ensures durability against harsh marine environments, including exposure to saltwater and various chemicals. Additionally, its excellent weather resistance guarantees long-lasting performance even under extreme weather conditions, making it a reliable choice for marine applications.

Another critical scenario where the LANMON FRP Mould excels is in the production of wind turbine components. Wind turbine FRP molds are crucial for fabricating blades, nacelles, and other parts that require precision and robustness. The smooth surface provided by the LANMON mold enhances aerodynamic efficiency and reduces surface imperfections, which is vital for the performance and longevity of wind turbines. The customizable nature of the mold allows manufacturers to create complex shapes and sizes tailored to specific turbine designs, while the chemical and weather resistance ensures the mold withstands prolonged exposure to outdoor elements.

Beyond marine and wind turbine applications, the LANMON FRP Mould is also suitable for various other industrial uses where high-quality fiberglass parts are needed. Its smooth surface mold finish contributes to improved aesthetics and functional performance of the final product. The combination of CNC machine control, strong chemical resistance, excellent weather resistance, and customizable mold type makes the LANMON FRP Mould a preferred choice for industries requiring reliable and efficient molding solutions.

In summary, the LANMON FRP Mould is ideal for occasions and scenarios including marine FRP mold production, wind turbine FRP mold fabrication, and other industrial applications demanding precision, durability, and a smooth surface finish. Its origin from China ensures cost-effective manufacturing without compromising on quality, making it a competitive option in the global market.

Customization:

LANMON offers premium Custom FRP mold services designed to meet diverse manufacturing needs. Our Fiberglass mold solutions are crafted with excellent weather resistance, strong chemical resistance, and superior corrosion resistance, ensuring durability and long-lasting performance. Manufactured in China, our Sanitary ware composite mold products feature customizable colors and a high-quality gel coat paint surface finish, providing both aesthetic appeal and functional excellence. Trust LANMON for reliable and tailored FRP mould services that deliver precision and quality.

Support and Services:

Our FRP Mould product comes with comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide detailed installation guidance, maintenance instructions, and troubleshooting assistance to help you achieve the best results.

Our team of experts is available to offer technical consultations and on-site support during the setup and operational phases. We also offer customization services to tailor the moulds to your specific requirements.

Regular training sessions and workshops are conducted to keep your staff updated on the latest techniques and best practices related to FRP Mould handling and usage.

Additionally, we supply high-quality replacement parts and accessories to maintain the longevity and efficiency of your FRP Mould. Our after-sales service ensures prompt response and resolution to any issues you may encounter.

For further assistance, detailed manuals and documentation are provided with every product, enabling you to maximize the benefits and lifespan of your FRP Mould.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!